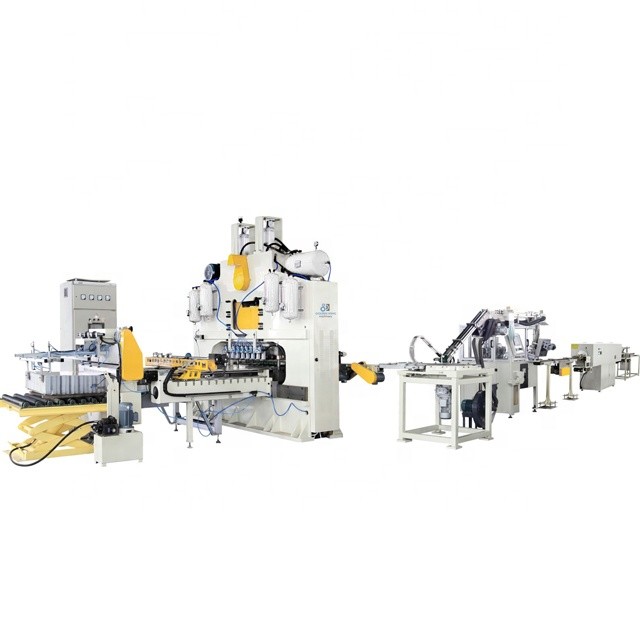

This machine is a high speed and high precision automatic aerosol caps production equipment. It is suitable for aerosol cone made by the tinplate. The whole sheet from the cylinder feedstock, automatic position pushing, servo feeding, mechanical hand stuffing , servo feeding, can stamping ,multi-station conversion stamping and forming, curling, lining, drying, automatic out of the caps to packing with fully automatic operation, no manual operation. The whole line equip with CNC high precision press, two-channel conversion press, curling machine, lining machine and dry machine.

This machine has the following characteristics:

1. Man-machine interface and simple operation.

2. Using the mechanical arm servo feeding, the automation degree is high.

3. Equipped with various alarm protection, safe and convenient to maintain.

4. Adopt the gantry bed, no gap guide running, when with high speed operation it has good stability and high precision.

5. Use the whole sheet blanking to improve efficiency and reduce the loss of raw materials.

|

Parameters

Mode

|

GT2A4-60 CNC press

(First feeding and stamping)

|

GT2A8-80 Conversion Press

(Conversion press and forming)

|

| Normal Pressure |

60T |

80T |

| Max stroke times |

200 |

150 |

| Max die installed |

3 |

2-channels(16 dies) |

| Max sheet size |

1100*1100 |

-- |

| Max sheet thickness |

0.4mm |

0.4mm |

| Total Power |

20kw |

24KW |

| Installation size |

2700*1300*2700 |

2500*1600*2700 |

| Total weight |

10.8T |

8T |

About us

We are a professional manufacturer & exporter specialized in various tin cans making machinery.

As a rich experienced manufacturer & exporter in this field, we always make the most suitable solutions for customers in tin cans / ends making.

‘High quality, competitive price & superior after-sale service’ is our principle.

We are always ready to develop long-term and good relationship with overseas customers.

We provide the following series of products:

Automatic Lid / Ring / Bottom Production Lines

Automatic EOE (easy open ends) Production Lines

Automatic Aerosol Cone / Dome Production Lines

Automatic Twist-off Lug Cap Production Lines

CNC Feeding System

Automatic Palletizer

Automatic Depalletizer

Wrapping Machine

Conveyor Device

Automatic Aerosol Tin Can Production Lines

Automatic Food Tin Can Production Lines

Automatic Beverage Tin Can Production Lines

Automatic Chemical Tin Can Production Lines

Fancy Can Making Machine

Semi-automatic 1-5L Round / Square / Rectangular Tin Can Production Lines

Semi-automatic 10-20L Paint Bucket Production Lines

Semi-automatic 15-18L Square Tin Can Production Lines

Semi-automatic 40-60L Bucket Production Lines

Press Dies and welding spare parts

And so on......

‘To be the best supplier’ is the attitude of our company.

We will keep on providing modern and advanced machines to bring greater value-added benefit for our customers.

If you want to know more about us, please don’t hesitate to contact us at any time.

Welcome to our company!

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!